The Role of Torque Wrenches in RF Cable Reliability

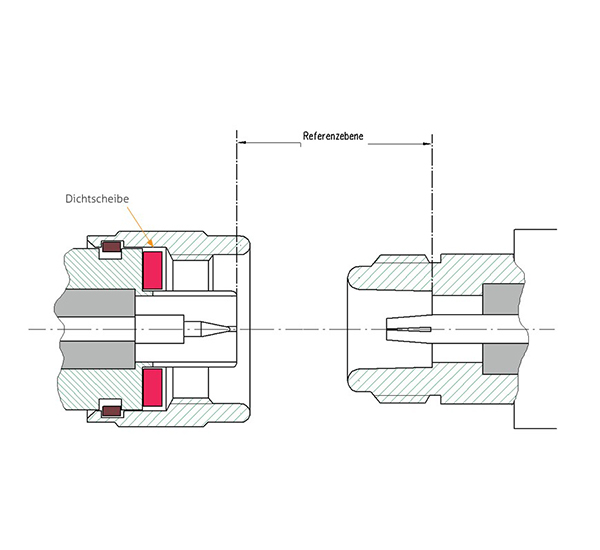

The N-type connector, developed in 1942 by Paul Neill at Bell Labs, is one of the oldest coaxial connector designs still widely used today. However, at the time, knowledge about RF requirements was limited—leaving the design with a few structural compromises.

One such issue: achieving a secure and consistent screw connection. Improper torque during installation can result in signal degradation, increased return loss, or even mechanical failure. This is where a torque wrench becomes essential.

Key Takeaways:

- Using a torque wrench dramatically extends the service life of coaxial cables and connectors.

- Manufacturers specify exact torque values for a reason—both to ensure RF integrity and to prevent damage.

- For N-type connectors, values range from 0.68 Nm (Huber+Suhner) up to 6 Nm (Telegärtner), depending on the brand.

- Inadequate torque can cause resonance effects and introduce narrowband signal reflections or mismatches.

- Our lab tests confirm that 1.6 Nm provides a secure, low-loss connection for standard N-type connectors.

“If the connector isn’t properly tightened, the dielectric seal won’t compress—and the electrical contact will suffer.”

– Stefan Burger, RF Expert

With the proper torque, both return loss and insertion loss remain within optimal ranges. As shown in testing, secure fastening prevents the resonant behavior that can otherwise block signal transmission in narrow frequency bands.

Whether you’re using SMA or N-type connectors, always tighten with a calibrated torque wrench. It’s a small investment that ensures consistency, longevity, and peace of mind in any RF setup.